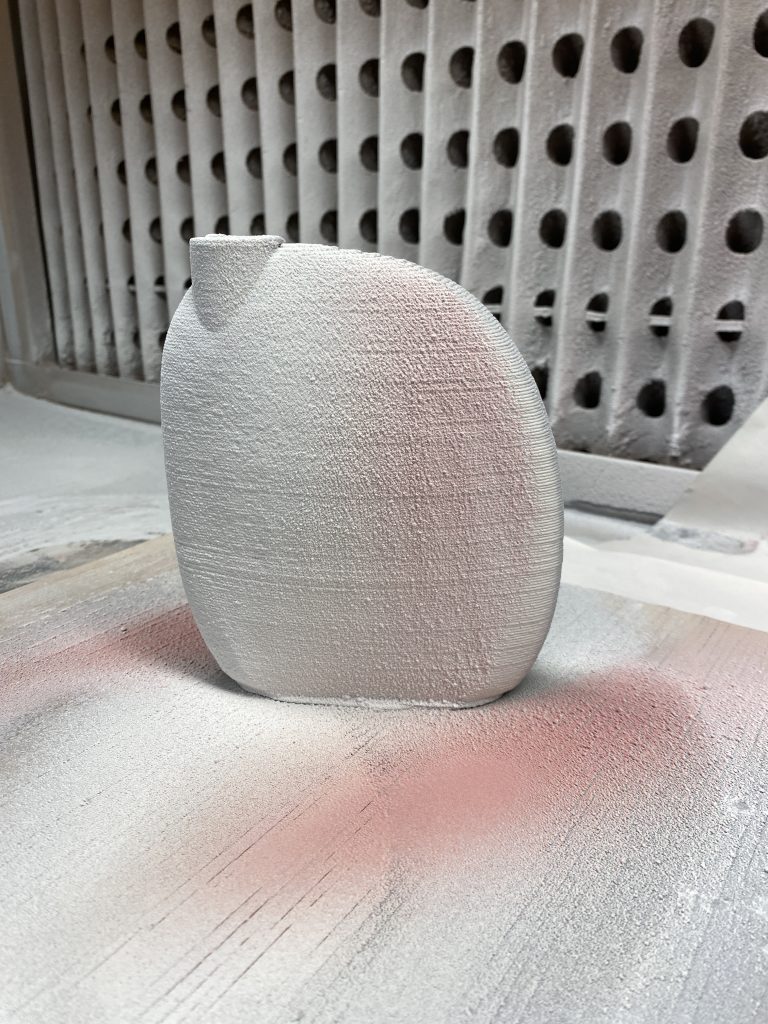

Why a flask? At the start of my Mdes studies I set out to make a 3D Printed clay flask, a counterpart to one that I had been making by hand for years. While the form is simple, translating the subtleties proved challenging. The form hints at stones, an ancient sacramental vessel, an amphora. Does it hold water or whiskey? Is it 100 years old? Or an object from the future? This vessel has become the means by which I am exploring this new technology, our relationship with it, and the wider implications of our designed objects. There is something both profound and comical in the relationship of hi-tech computers, mud, and maker. Clay is sticky, the muck of old organisms processed geologically. Computers are rational, efficient and exacting. When 3D printing clay, we take mud and push it through shiny parts, the sum of our tool making knowledge and refined commodities. Below are some iterations with different firing types, clays and glazes. The materials have been both foraged and purchased, mined by me, and by large machines. Fired in the woods and in commercial kilns.

I’ve been spraying surfaces onto 3D Printed ceramic forms this week. I get lost in this process. The glaze sediments onto the surface and I think about layering, building a texture. This is a matte cone 6 glaze that I am working with. The first two are made with entirely commercial materials. The last piece is sprayed with an ash glaze that was made from the ash collected on the North Complex Fire.