Wrapping the warp

So normally you use a warping board to set up your warp, but I didn’t have one, nor did the soft shop. I could have made one in the wood shop, but I got impatient, I wanted to get to the weaving part. So I used what I had available to me, table legs. I am not sure if my Aunt Norma would be proud of me or horrified. She had taught us how to measure the threads per inch, to use a chart and a project plan to calculate and project how much warp we would need, and then to weigh the threads to reduce wasted yardage and materials. I did none of this. I don’t even know how long my warp is. Its on the small side. It’s one table longwise and one table width wise, and the cross is not as close to the end as it should be, it is where the table legs allowed it to be. I have a vague idea of what I want to make with the woven cloth. I have this fanny pack I love to use, and some extra zippers stashed away. I figure I can make a nice series of fanny packs to give to friends, or maybe sell if people like them.

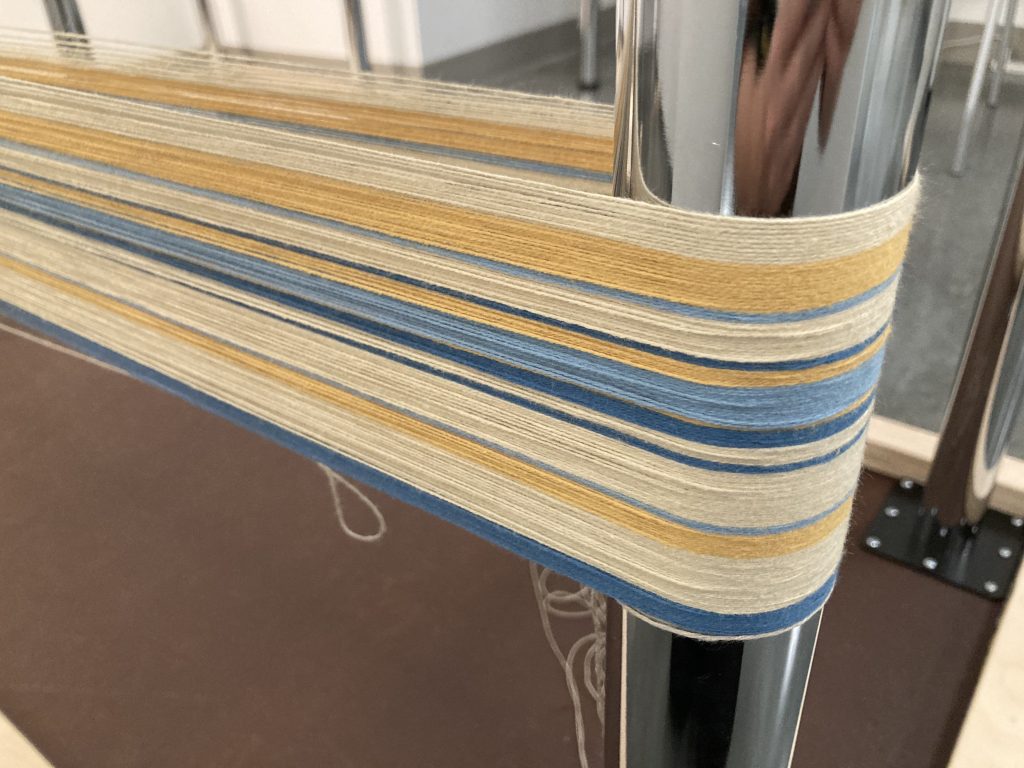

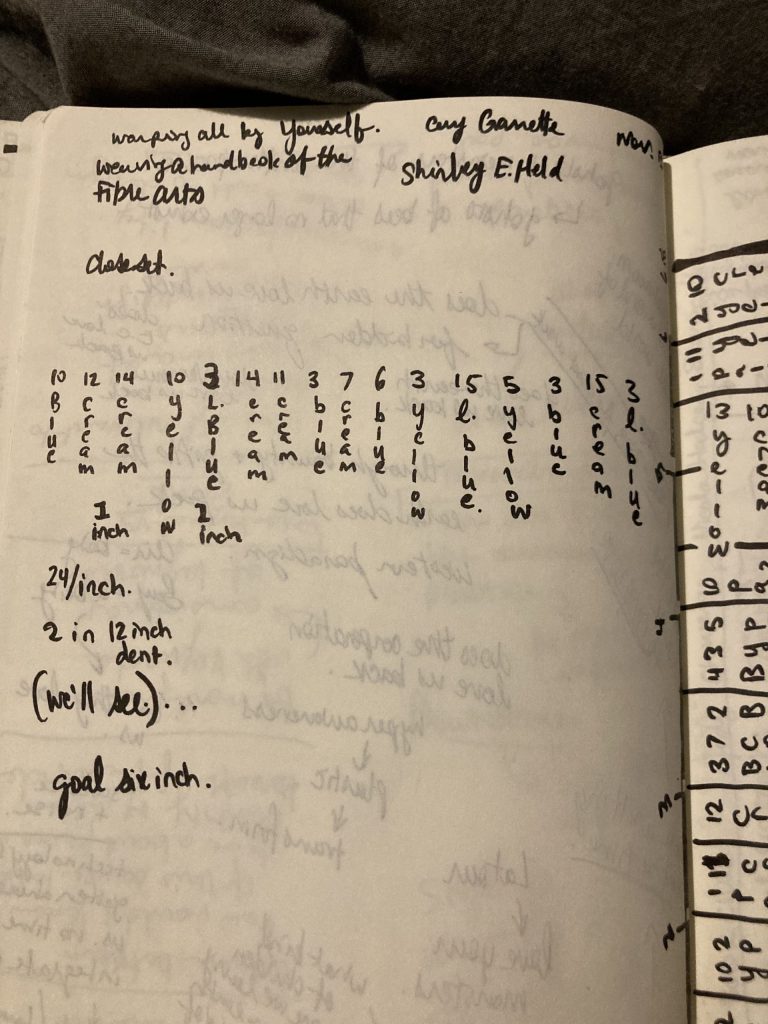

I was thinking about data while I was winding the warp, particularly inspired by Chloe’s work, and her ability to take her personal data, filter and interpret it through experiential actions. Garima is in the studio the day I wind the string. We talk about data, computation, and critical fabulation. There is something so mathematical about planning a weaving project. We talk about the validity of data, and Garima points out that I am making decisions to change the colour at certain points. There is a rationale behind the colour changes. I am not translating a data set into the warp, but the warp itself is becoming the data-set. There is a proportionality I am maintaining as I wind. 24, 12, 6, 4, 3. somehow the pattern relates back to the number 12, divisible by/into, or adds up to 12, I have decided to use a 12 dent reed, which is the smallest I have, that means I can have 1 thread per dent, and get 12 threads per inch, or 2 threads per dent and get 24 threads per inch. Or I can create a pattern where I make the weft shift from tight to open. I probably should have planned more before I started, but I like that I am learning by doing.

Time all by yourself

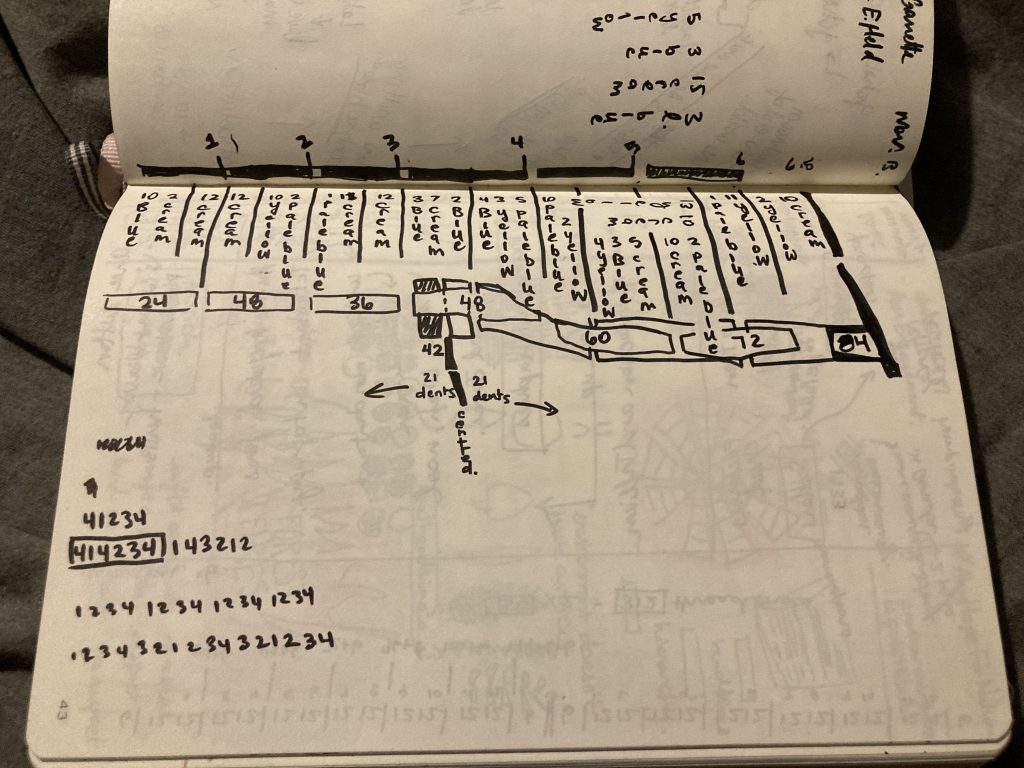

I enjoyed the process of dressing the loom but realized that this work would definitely be easier with more than one person. I felt pretty fortunate to have this book in my collection. I also had a DVD that I could play at home on Bill’s Xbox with tips on how to dress a loom, and my notes from 4 years ago when my mom and I were being taught by my Aunt Norma. I did start to feel a bit of anxiety, because I assumed I could get the loom dressed in a day and start weaving right away, Instead the week came to a close and I had gotten as far as making the warp, getting the warp tied onto the back beam, making new lease sticks to replace the ones that got lost in shipping and getting the threads spaced through the rattle. I started to wonder though, in this project and the dying project, and even with the embroidery I have started to do, I keep referring to books. I think I am afraid to proceed without doing my homework/research first. Sometimes I wing it and improvise as I go, but I keep noticing a tendency to want to check-in and make sure I am doing it right. I think in non-pandemic times I prefer to learn from someone. To watch how they do it or have someone there to ask a question when I get stuck. I wonder if this is a colonial way of learning, and want to bring more awareness, spend more time noticing when I hold back and wait for confirmation before proceeding. I admire the trait in others where they just go for it and develop their process as they problem-solve along the way. Maybe I am overthinking it, I had books to reference, but I still made lots of mistakes, and I still had to improvise along the way.

Spacing out the threads

So before I could untie my warp and start spreading it out I had to make some new lease sticks, there is this amazing trick of putting a cross in your warp that helps keep your threads in order while you get it onto the loom . The lease sticks help you maintain your cross through the next bunch of steps dressing the loom, you only take them out at the very end right before you start weaving. The rattle is a cool step too, it helps you space out the threads, and keep them in order while you wind the warp onto the back beam. I remember Aunt Norma saying that keeping good tension through this phase was important. So, I try to work steady and methodical. I also have to make some decisions. How wide will my cloth be, what am I going to do for the tie up pattern, and threading the heddles, I really don’t know what I am doing. My mom is a beginner as well. She doesn’t have answers for me, but talking it through with her makes me feel more confident. Its actually pretty nice, I spent a lot of FaceTime with my mom this week. I think she enjoyed hearing from me, and seeing what I was up to. As I worked, I started to come up with ideas for modifying my tools and process, for the next warp, I would like to build a new rattle. My mom built that one to go into the beater bar, but I think I want to build one I can clamp to the the top castle bar. That way I can work standing up, I think it would make the next step of threading the heddles easier too. Or not.

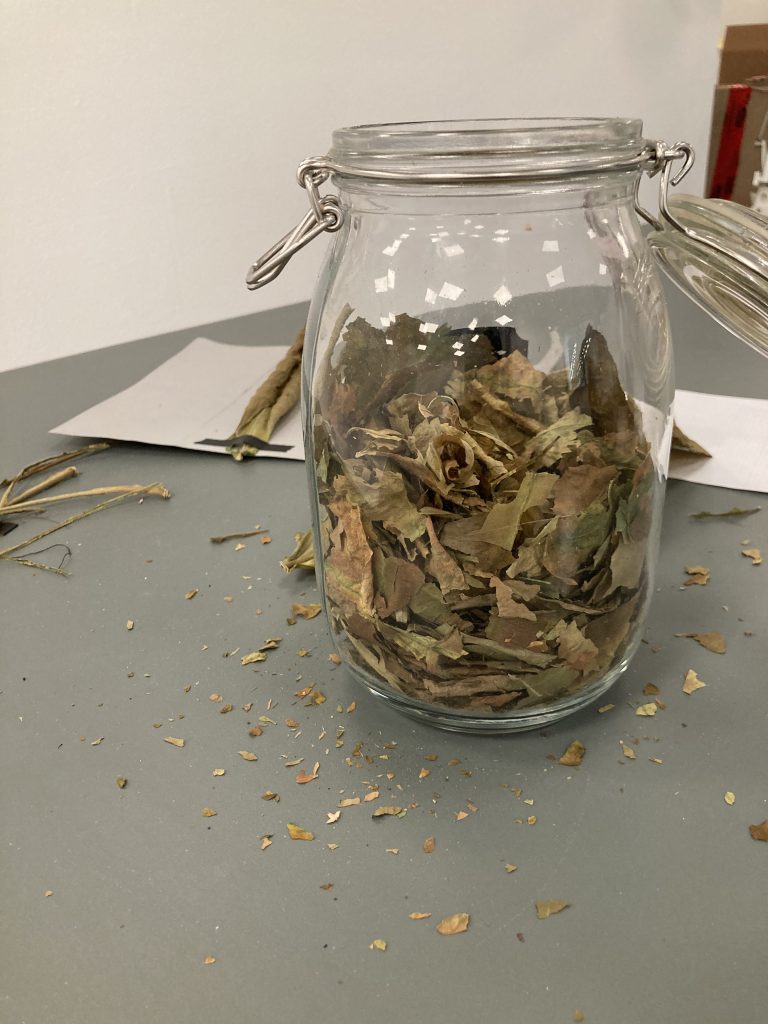

Crunching time

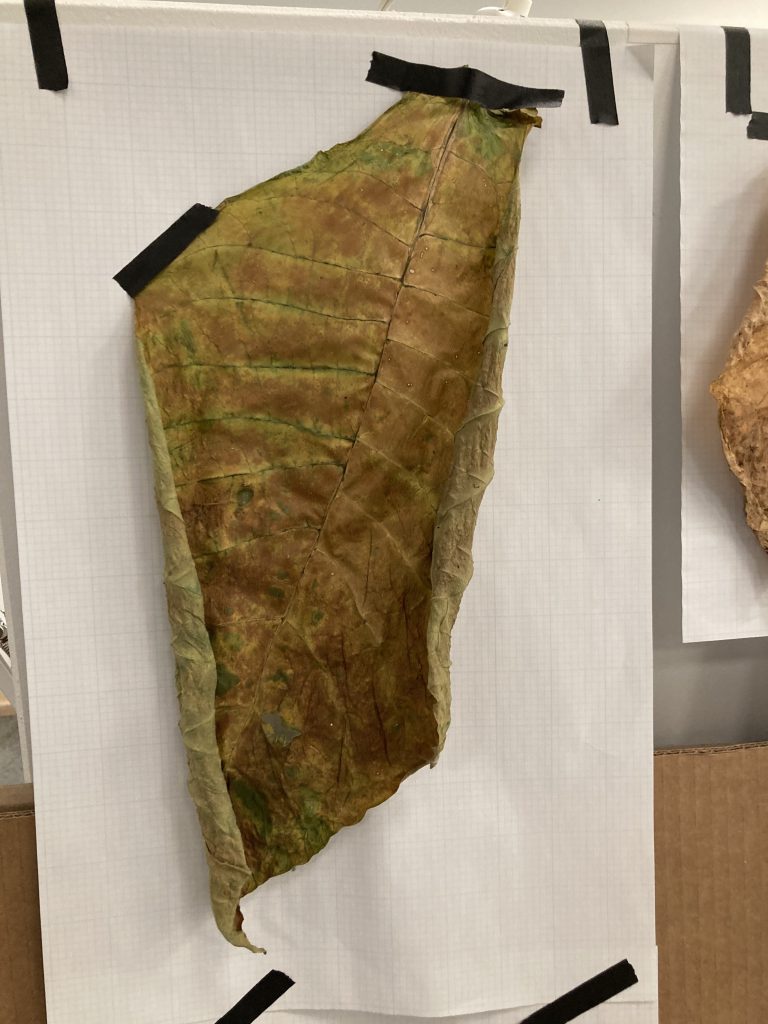

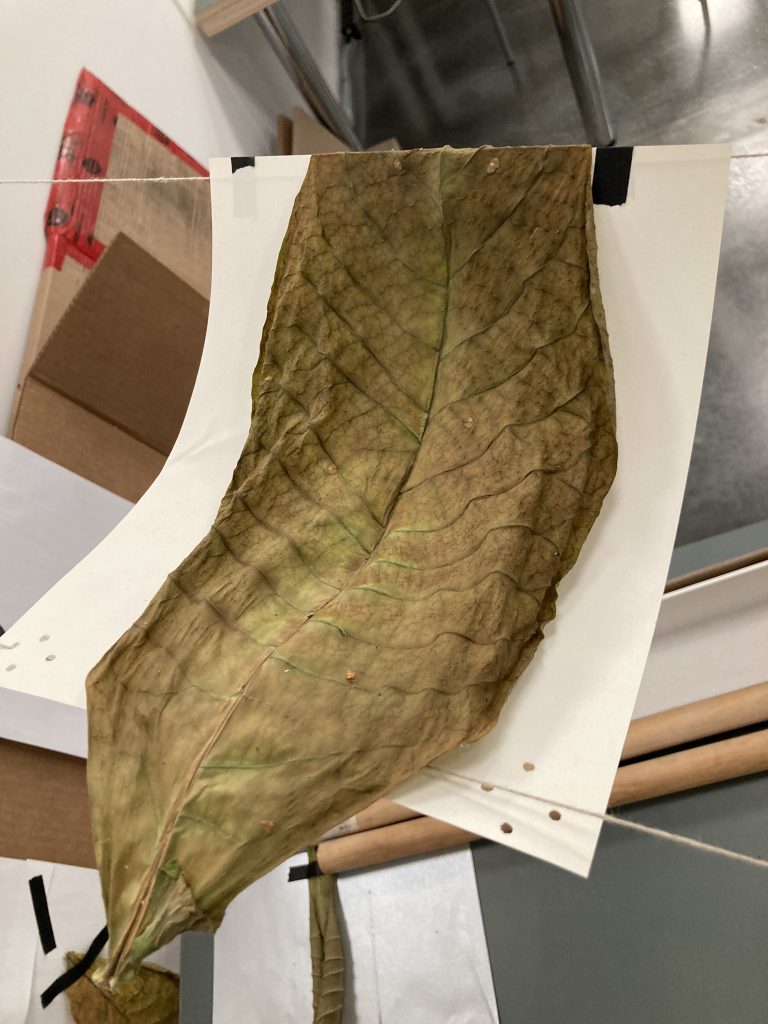

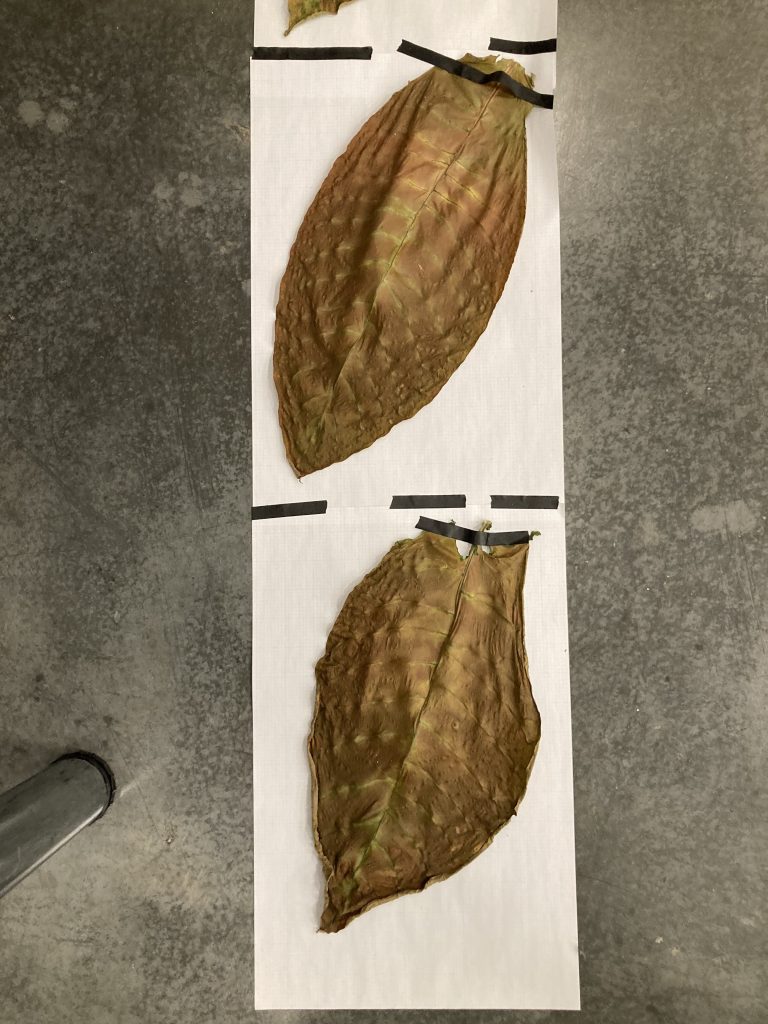

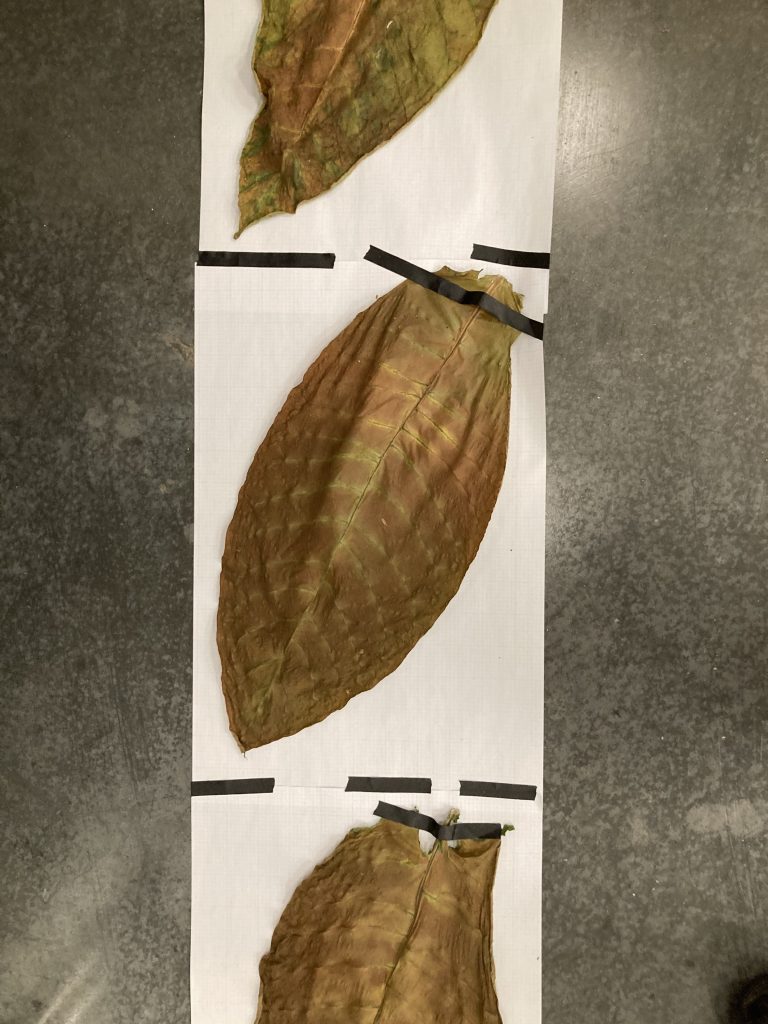

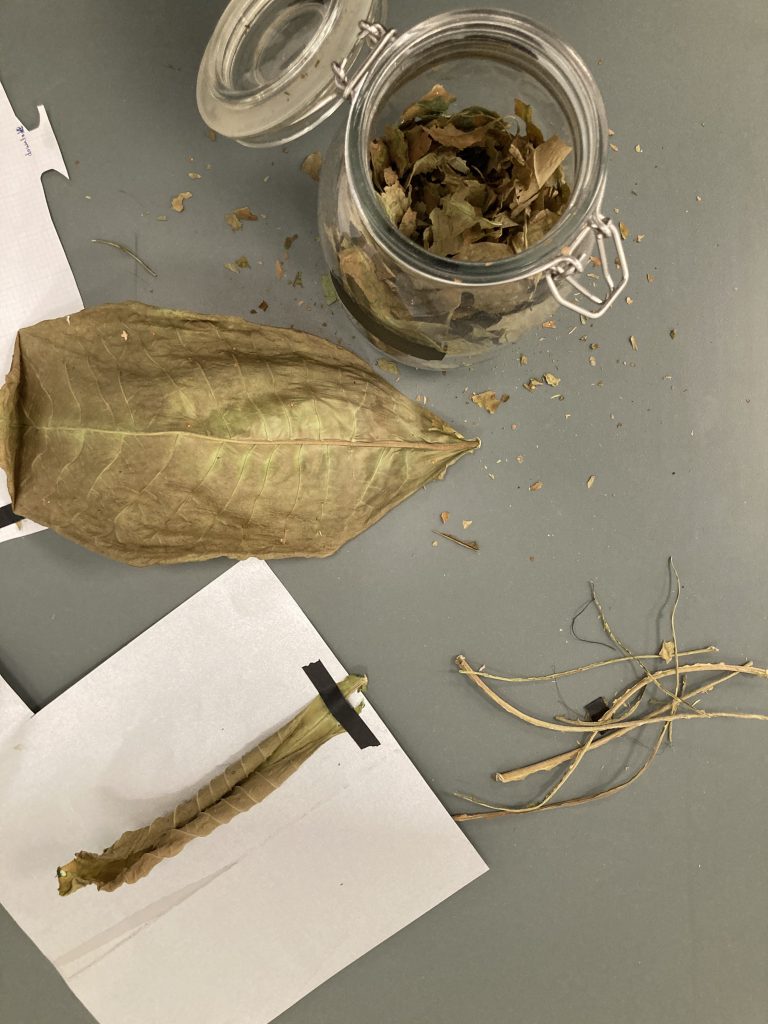

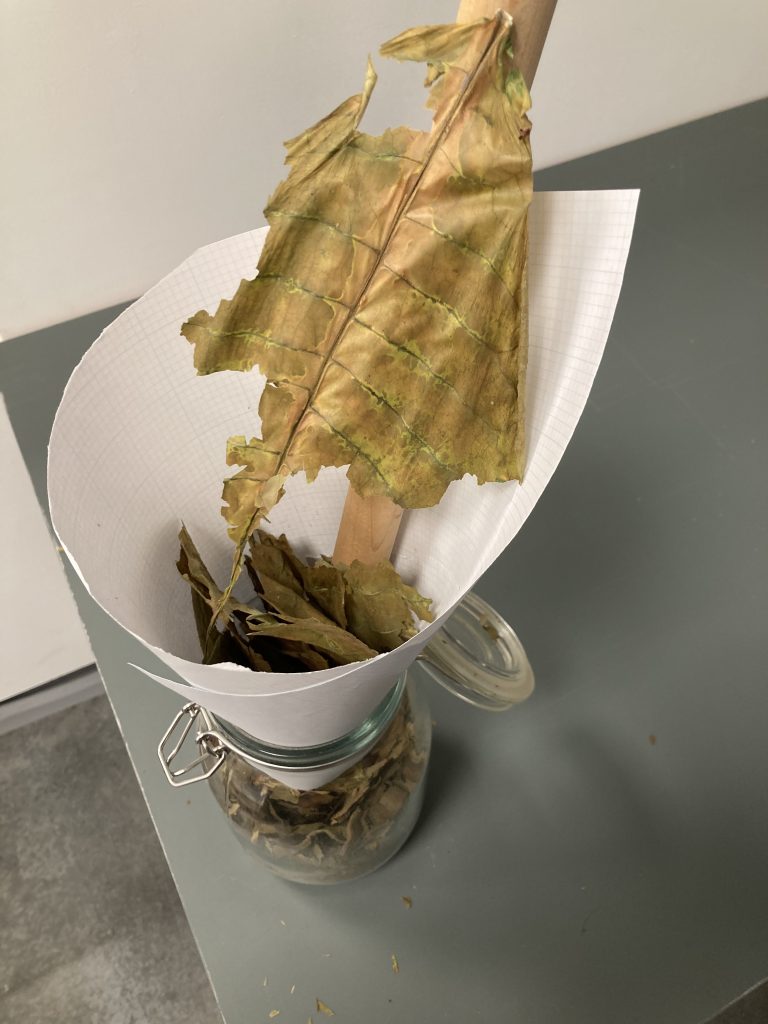

The tobacco leaves had dried out and become crispy, it seemed like a good time to process them. I still had no idea what I was doing, but knew they should be cured, so I got a glass jar, and started breaking the leaf matter away from the stems to fill the jar. I couldn’t believe how much tobacco I had harvested. In order to keep making space in the jar I took a wooden dowel and used it to crush the leaves further. It was messy, it made a satisfying crunching sound, similar to eating potato chips. My fingers got sticky from the tobacco residue. I am still curious, why is tobacco used as a way to show gratitude when harvesting. I know that nicanoides, a type of insecticide, are made from the nicotine in tobacco, I wondered if it is the insecticidal properties that in small doses increase the health and well being of the plants and ecosystems being harvested from. Next year I will move from drying to curing a little faster. The smell I associate with tobacco has just started to form, and is still pretty faint. I wonder if I let them dry out too much before transferring to the jar.