Wobbly Wood

The aim of this initial project was to get the steam-box system I was using to bend wood to functional status, and additionally to perform some simple experiments with bending wood to get a feel of the kind of force it takes, spring back, potential problems, etc.

These initial tests were conducted with 3/4 x 1 1/2 inch oak. Oak was chosen as it’s one of the woods that’s actually able to be bent using this method, and it was cheap.

During the first test, I soaked the strip of wood for 1 hour before placing it in the steamer. Since this was when the box was at its leakiest the temperature varied greatly between 150 and 210 deg F. After several hours of varied temperature I removed the piece of wood with the intention of clamping it to a brace, unfortunately, the angle of the brace was too aggressive and I was only able to achieve a mellow curve with a slight twist before the wood began to split and lignin reharden.

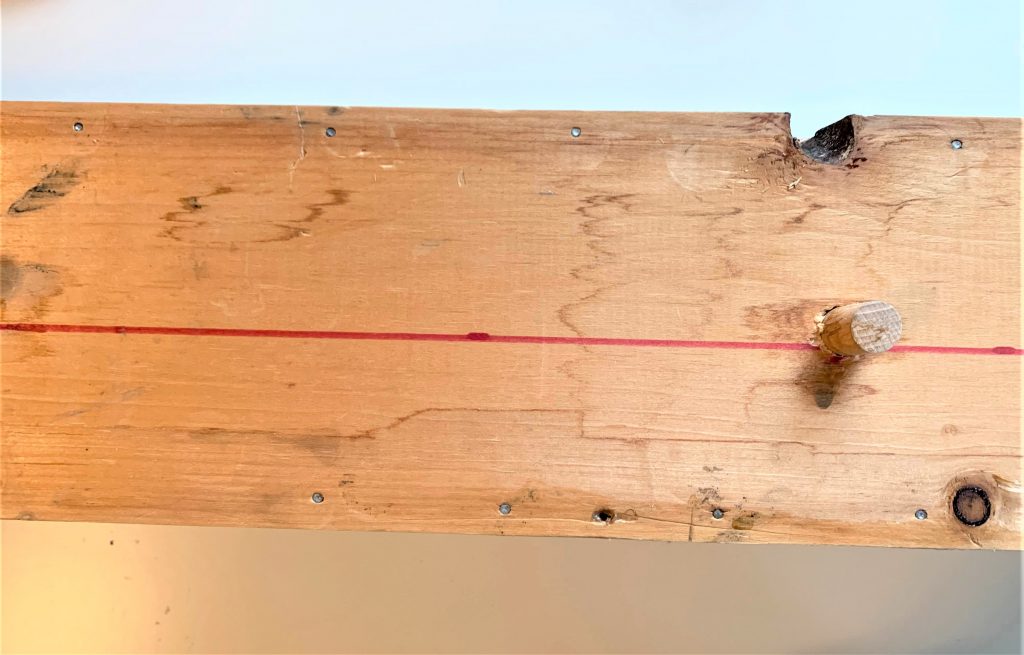

As you can see in the photo, the split occurs along the grain of the wood where it runs out to the edge. This is to be expected and ideally, pieces without knots and whose grain runs as far down the length of piece as possible should be selected.

After spending an afternoon re-sealing the steamer I began soaking the new test strips. They soaked for 2 hours before being placed in the steamer with the hope of moisture penetrating the wood more. Ammonia can also be used to steam wood, as it’s able to penetrate deeper to heat the lignin. but requires greater ventilation and safety requirements. I’m working from home and hope to remain on good terms with my landlord.

Once in the box, which held much steadier at 215 deg F the first piece was removed after an hour and 20 minutes. This was the smallest piece and did not yield much pertinent information.

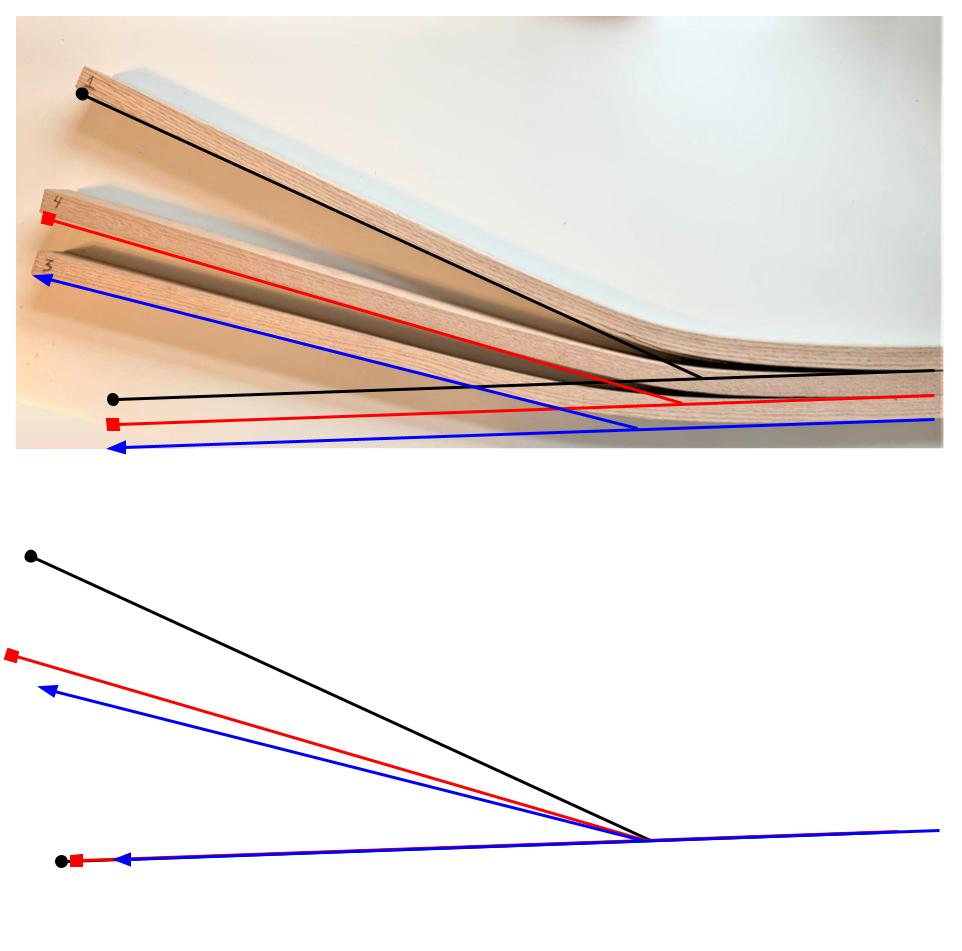

The third and fourth tests were to experiment with spring back. I used the first piece I bent as a curve to emulate and clamped the new piece to it. The third test was left clamped for 20 minutes before being removed, and the other was allowed to sit overnight. The third piece steamed for 2 hours and 40 minutes while the fourth steamed for 3 hours.

As the photos show, while both pieces sprung back, the fourth test held the curve more accurately. The mould piece was bent at an angle of about 27 degrees, while the 3rd test bent to about 16 degrees and the final to 18 degrees. Going forward I’ll exaggerate the shape of the bend by 30-35%.

The next steps now are to cut a rocker-camber-rocker mould and begin testing pressing a flattened ski into shape. I’ll use what I learned from my own spring back tests as well as additional online resources to exaggerate the curve as needed. With the mould and shape as the constant, I hope to start experimenting with different kinds of wood to see what mechanical properties they yield.